simulation and modeling - in short

Innovate MedTech products and shorten time-to-market with Simulation & Modeling

Create better products, avoid expensive mistakes during product development and get your medical device on the market sooner. Simulation & Modeling is a powerful tool for experimenting with product prototypes in a fast and cost-effective way, and the Technolution experts are ready to help your organization get ahead of the competition.

simulation and modeling

Our capabilities

Whether your organization needs a single of our competences or the entire range, we are here to help you.

simulation and modeling - the long read

How can Simulation & Modeling be applied to development of devices?

By developing medical devices with a traditional trial-and-error approach, your organization risks using unnecessary time and budget. Why not use a proven method to cut down on the number of prototype iterations during a development project?

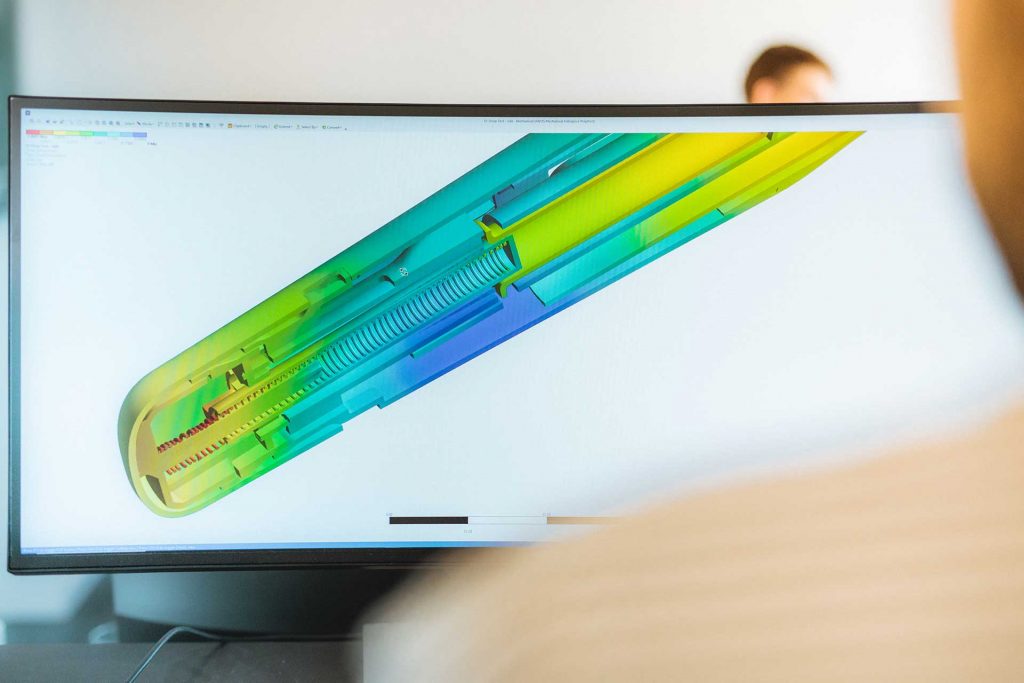

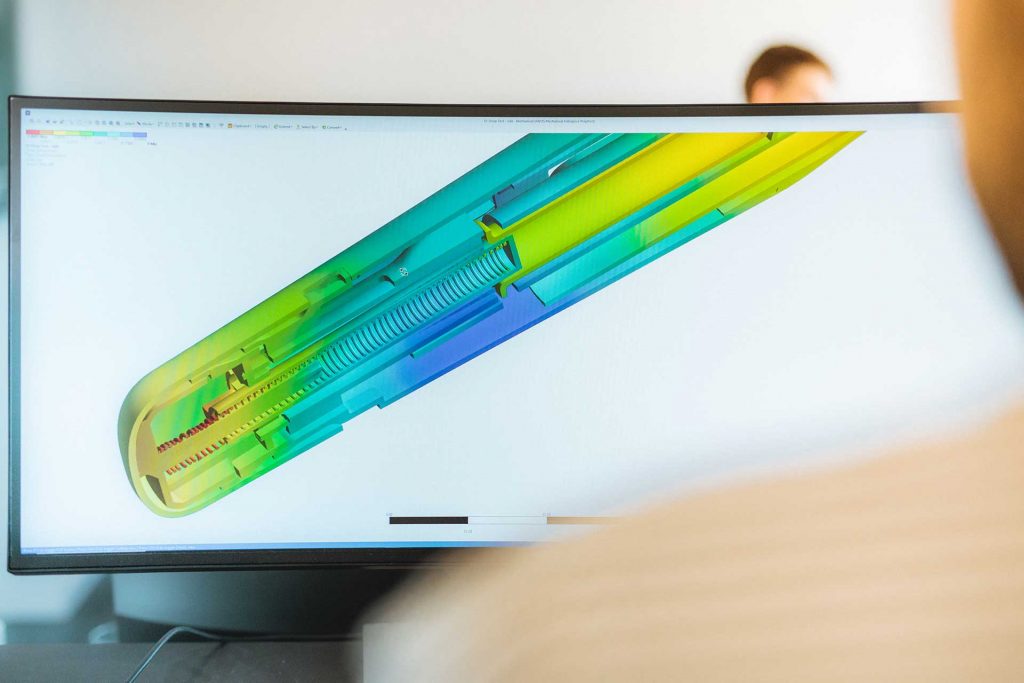

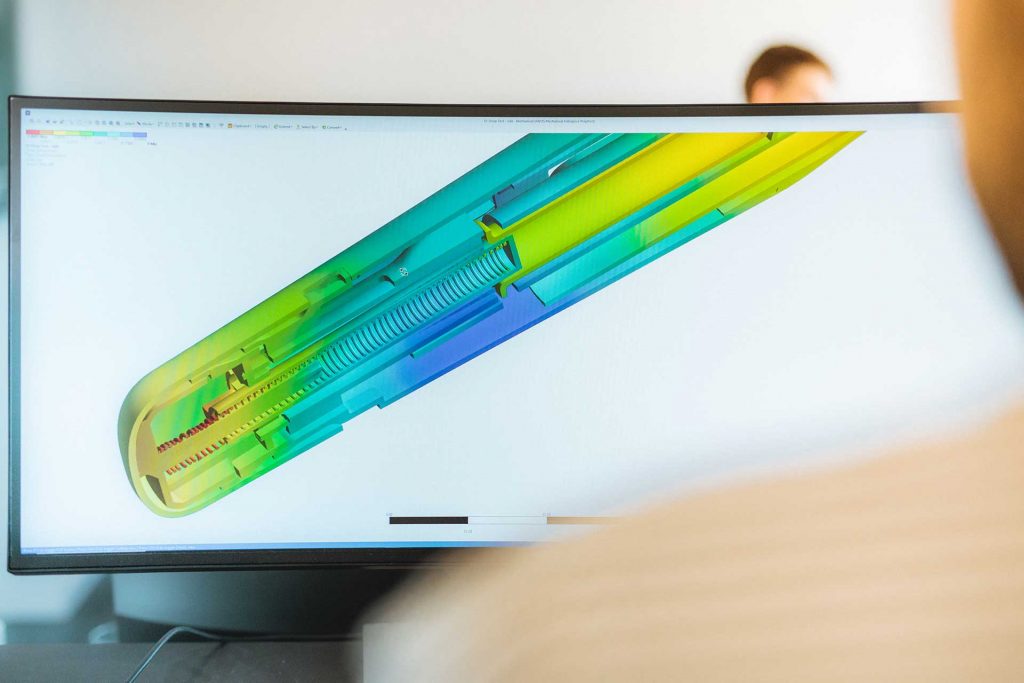

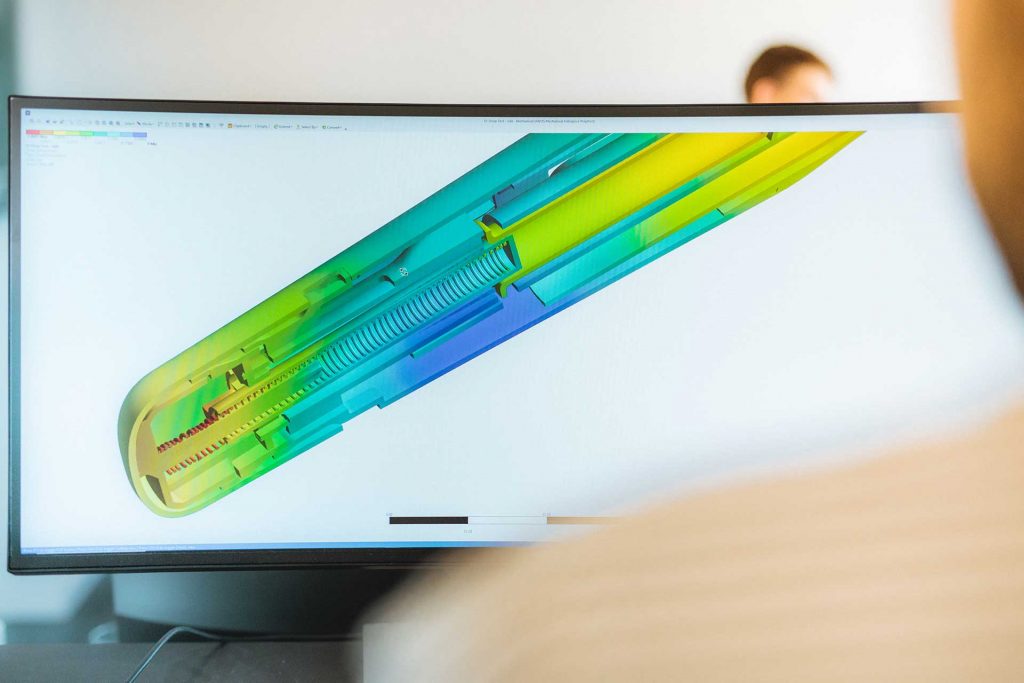

The intricacies of modern medical devices can make it difficult to grasp the complex relationships of the many parts inside a device. This is where Simulation & Modeling really becomes a no-brainer for getting a scientific and analytical view of the device that helps your organization avoid costly and time-consuming failures.

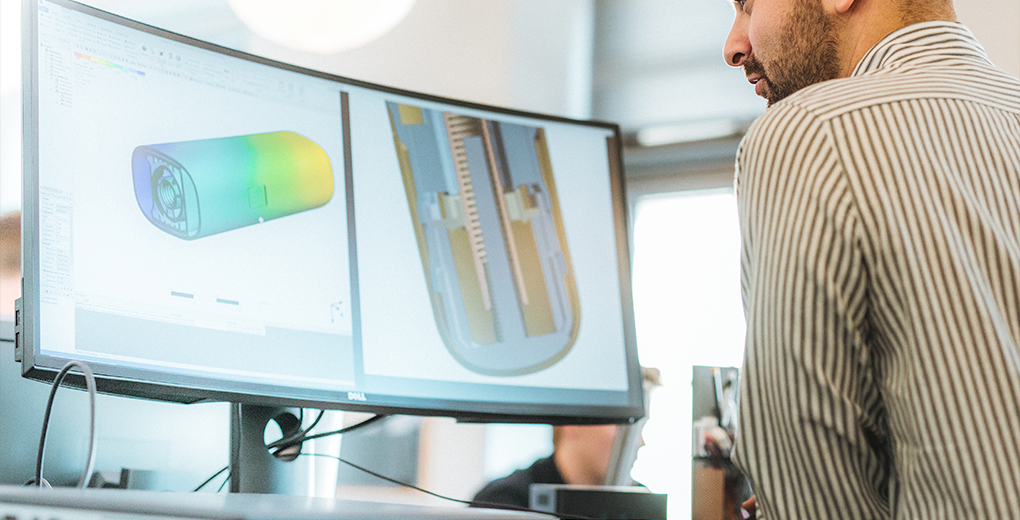

Our Simulation & Modeling experts can help you gain early insights and get sound scientific data for the performance and behavior of the device being developed, based on, among others, the Finite Element Method (FEM). At Technolution, we review our Simulation & Modeling processes critically, thereby ensuring that our computer models have been thoroughly validated. Our material models are furthermore developed specifically for the most widely used polymers in the MedTech industry and can be customized to our clients’ needs.

At Technolution, seasoned professionals work alongside fresh talent to create a pioneering culture with a strong team spirit. With ten areas of expertise, we are a hub of knowledge and innovation based firmly in the world of MedTech. Whether working in-house or at our clients’ premises, we engage with stakeholders in a professional and friendly manner. We are nerdy experts that are respectful towards colleagues and clients, but at the same time are not afraid to ask difficult questions and challenge the status quo.

Want to know more?

Get in touch

Do you want to know more or didn’t you find what you were looking for?

As Head of Simulation and Modeling, Alexandre, also called ‘Sandro’, will be pleased to receive your enquiry.

What we do

We have the expertise to take you from A to Z

Whether you need a single competency or a combination of skills, our experts are ready to assist you through the entire development process. Based on the specific needs of the project, we assemble the ideal team of specialists.

Since joining forces with the MGS Group, we are able to integrate advanced manufacturing knowledge into the earliest design phase and minimize the number of iterations. Our complete offering takes your project seamless through the entire value chain ensuring faster time-to-market combined with minimized risk. What’s not to like ?

related cases

Cases you might be interested in:

How Early Stage drop test simulations can uncover hidden design optimization insights

Learn from ALK’s success with Technolution’s experts, gaining crucial insights for smoother testing and reduced project risks.

What are the Benefits of Simulation with the Finite Element Method?

Will a medical device break apart when dropped onto a concrete floor? Does the device remain safe and functional if stored for years on a shelf before reaching the patient?

Why you should apply virtual DoE to the design process

Early product insights and fewer physical tests are some of the benefits of using Design of Experiments in medical device development.