alk cASE STORY

How Early Stage drop test simulations can uncover hidden design optimization insights

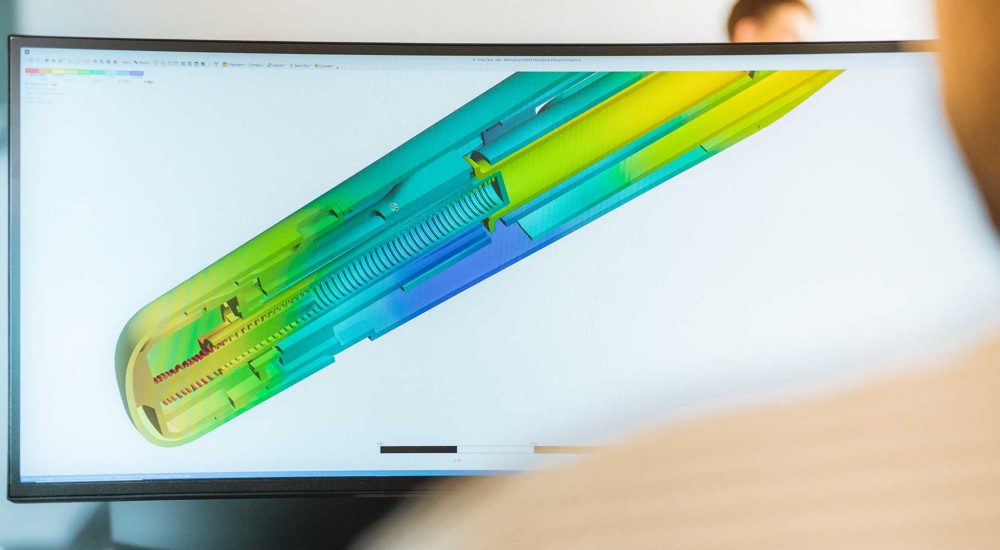

ALK wished to front-load the testing activities for their novel-feature drug delivery device in an attempt to reduce uncertainty about the coming drop tests. Our simulation experts created a virtual twin of the device which not only provided important insights on drop test performance, but also revealed hidden issues and opportunities in time for a design iteration.

THE SHORT VERSION

Challenge: Our client wanted insight into the expected drop test performance of their new device.

Solution: We created a virtual twin of the device and ran drop test simulations as well as other simulations.

Result: The client not only gained assurance that their new device would be able to pass the drop tests, but also gathered valuable input for design improvements.

background

Why ALK decided to use simulation and modeling

A key requirement for regulatory approval of a new drug delivery device is a series of standardized drop tests that demonstrate the device’s ability to maintain its key functionality after falling from certain heights. When ALK was in the early stages of developing their new combination product for drug delivery, they chose to use simulations to front-load the testing activities and gain faster insight into their product’s behavior under stress.

A major concern when developing a new drug delivery device is passing the drop tests required for obtaining regulatory approval and taking the device to market. For device developers, one of the highest priorities is to reduce uncertainty and prevent unpleasant surprises, especially once the project has advanced to the later stages. For ALK, a Danish global leader in the field of allergy treatment, this led to the decision to start gathering product data and insights at an early stage of their development project, and Technolution’s simulation and modeling experts came on board to assist.

Uncovering hidden information with simulation and modeling

Initially, the main purpose of running simulations was to tackle the high degree of uncertainty associated with the novel features of the device under development. Performing a series of drop test simulations was expected to give an indication of how the device would perform during physical drop tests, and these expectations were met. However, the data delivered by the device simulations exceeded the initial expectations and provided insights that would have been impossible to obtain in any other way.

This is because a full device simulation creates a virtual twin of the physical device, which is in some ways comparable to gaining X-ray vision into the inner mechanics of the device. In the physical world, something similar can be achieved by drilling and filming the impact using a high-speed camera. However, this approach has its limitations, and could alter the device properties enough to render the test results unreliable.

Drop test simulations allow you to peek into the future

With the information uncovered by the virtual twin, the project team gained valuable insights into the detailed properties of the device. They now had the possibility to predict its behavior under stress, which gave them a sneak peek into the probable outcomes of the future drop tests. Armed with these early insights, the team was in a better position to shape the future physical test scenarios, thus reducing uncertainty and increasing predictability.

Another benefit provided by the simulation data was the possibility to anticipate potential design problems that would otherwise only have been discovered later. These insights provided input for design evaluations and reworks at an early stage when time pressure is typically lower and changes are less costly to make.

Device simulations provided a head start on prototyping and testing

The decision to perform device simulations early ensured there was enough time to use the available information to the greatest possible advantage. It gave the team the possibility to iterate on the device design before releasing files for prototype manufacturing, which eliminated problems that could later have appeared during the physical tests.

By front-loading the test activities with drop test simulations, the team had a large amount of device data available at an early stage rather than having to wait for physical tests. This contributed to a reduction of the late-stage test load and helped ease the burden of tasks that often tend to pile up towards the late project stages.

testimonial

testimonials

What people say?

Simulating drop test scenarios beyond minimum requirements

As opposed to physical tests that require considerable amounts of time and money to carry out, with computer simulations it is relatively fast and easy to change parameters and test a larger number of variations. In the ALK project, this meant that the project team did not have to limit themselves to only addressing the minimum of test cases required for obtaining regulatory approval.

This advantage was used for expanding the test case scenarios and going beyond the standard test cases prescribed by regulatory requirements. The team decided to include a number of typical use case scenarios in the device simulations, which added valuable knowledge about the device and its behavior during various types of impact.

Lowering overall project risk with drop test simulations

Technolution’s role in this exciting process was conducted by our Simulation & Modeling team, who created a virtual twin of the device in Ansys LS-DYNA and used it for assessing the device design and emulating the physical drop cases.

The objective of the drop test simulations was to reduce project risks and secure the planned launch date for the client’s new combination product. With the data gathered from the simulations, our client not only gained assurance that their device would be able to pass the necessary drop tests, but also obtained detailed insights into the properties of the device at an early stage of the development project.

What we did

We have the expertise to take you from A to Z

For this specific challenge and the solution of it the highlighted areas of expertise were in play:

Related cases

Cases you might also be interested in:

9 product families submitted for approval in timely MDR transition project

Transitioning from MDD to MDR compliance touches on several different business processes – all happening within a strict deadline. Therefore Ambu A/S decided to initiate the process well in advance and team up with Technolution..

Fast-tracking proof of concept with strategic use of Scoping

A unique private-public collaboration proved it possible to take several years off the preclinical investigation phase and fast-track the project to clinical trials.

Philips Healthcare IntelliSave AX700

A full Risk Management process was developed for a new anesthesia workstation. We facilitated the development of documents and procedures to speed up the CE marking for the current device as well as future development projects.