AMbu A/S

9 product families submitted for approval in timely MDR transition project

Transitioning from MDD to MDR compliance touches on several different business processes within a medical device manufacturing company while at the same time imposing non-negotiable deadlines for submission of documentation.

Add to that the need for ramping up a variety of activities for a limited time, and you have the situation at the outset for Ambu A/S, global supplier of Anesthesia, Patient Monitoring & Endoscope Solutions.

case story

The short version

Challenge: Ambu A/S requested assistance for the MDR transition of nine product families within a period of two years without any interruption in product supply or impact on ongoing innovation activities.

Solution: Technolution handled project management and brought the required subject matter specialists into the project as needed to ensure the appropriate level of documentation. The first submissions were done six months before final deadline and after that, regular submissions made sure all products were ready in time.

Result: The timely submissions of device documentation included 18 STED files and ensured our client’s continued supply of anesthesia products and solutions to the European markets, contributing to the total 2021/2022 revenue of more than DKK 200 mill.

For their MDR transition of nine different product families in the anesthesia category, Ambu A/S decided to initiate the process well in advance of the expiry of any current certificates.

In August 2020, Ambu A/S chose to partner with Technolution and handed over the project management role to their quality management specialist and set up a collaboration between Ambu and Technolution subject matter experts.

From the very beginning, the essential requirements for the project were clear: ensure uninterrupted supply of the devices while planning and executing all tasks with no impact on the ongoing innovation activities.

The road to MDR compliance – planning and staying on track

The update of the device documentation to be finalized two years into the future was planned by the project group with a strong focus on cross-functional coordination.

The project plan included careful prioritization of the products in order of importance and was executed with continuous attention on keeping the project on track.

The first products ready for MDR approval were submitted to the notified body in December 2021, and in the period up to July 2022, regular submissions made sure all products were ready in time for the final deadline.

During correspondence between notified body and internal regulatory affairs, Technolution’s quality management specialist coordinated with the subject matter experts at Ambu A/S to gather the necessary information for responding to the requests.

MDR transition accomplished: to the finish line and beyond

In the MDR transition project completed together with Ambu A/S, Technolution has mainly assisted with project management and subject matter expertise in the fields of quality management, design control, and test & verification.

The timely updates and submissions of device documentation included 18 STED files and ensured the continued supply of key products and solutions within Anesthesia to the European markets, contributing to the total 2021/2022 revenue of more than DKK 200 mill.

testimonial

What people say?

What we do

We have the expertise to take you from A to Z

For this specific challenge and the solution of it the highlighted areas of expertise were in play:

Related cases

Cases you might also be interested in:

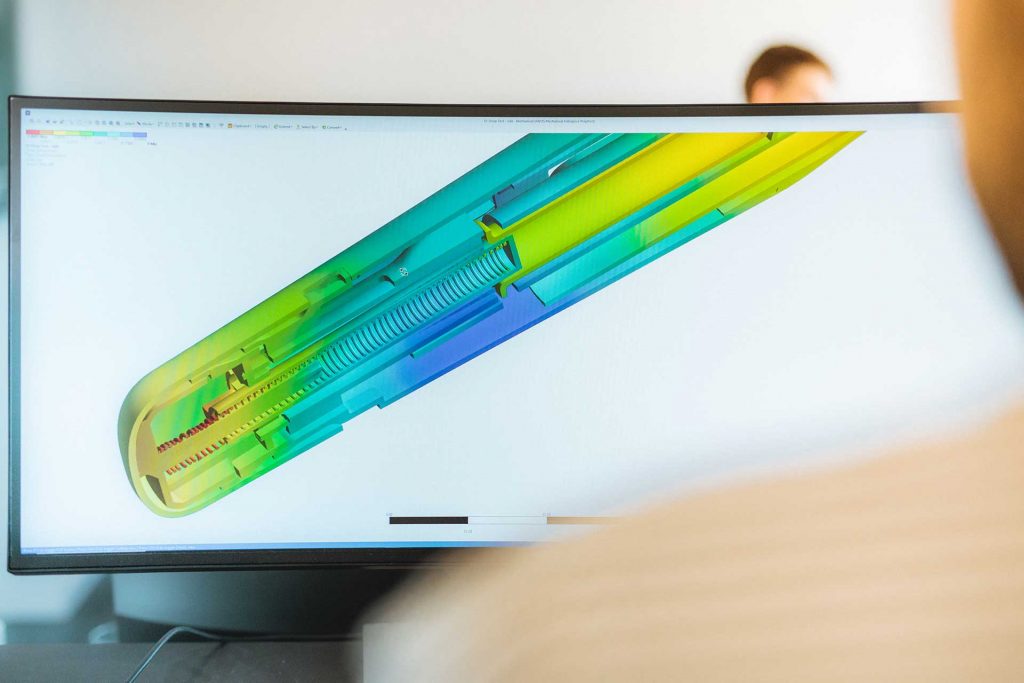

How Early Stage drop test simulations can uncover hidden design optimization insights

Learn from ALK’s success with Technolution’s experts, gaining crucial insights for smoother testing and reduced project risks.

Fast-tracking proof of concept with strategic use of Scoping

A unique private-public collaboration proved it possible to take several years off the preclinical investigation phase and fast-track the project to clinical trials.

Philips Healthcare IntelliSave AX700

A full Risk Management process was developed for a new anesthesia workstation. We facilitated the development of documents and procedures to speed up the CE marking for the current device as well as future development projects.